CME-55 Skid Mounted Drill

Optional Equipment

Rubber Tire ATV Mounted Drills | Truck Mounted Drills | Track Carrier Mounted Drills | Trailer Mounted Drills | Skid Mounted Drills

55 Features | 55 Specifications | 55 Optional Equipment

Automatic SPT hammer†

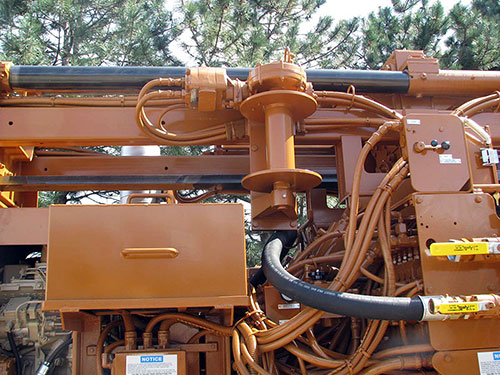

Hydraulic rod holder and breakout wrench†

The hydraulic rod holder and breakout system makes your job quicker and safer. The system not only pivots from on-hole to off-hole positions, but also hydraulically moves in and out. For efficient operation, the breakout wrench is mounted at the pivot point of the rod holder arm.

Slide bases make the job easier and quicker

Slide base options are available for both in-out and sideways movement of the drill on the steel skid frame.

Quick mast disconnect†

This feature, along with the quick-cabling sheave options allow you to remove the mast when working inside buildings, underneath bridges or in other low overhead drilling locations.

Patented angle drilling system†

Cone Penetrometer Testing (CPT)

CPT controls allow you to easily switch from typical geotechnical drilling and sampling procedures to pushing a cone. A dedicated hydraulic circuit including detented CPT control lever, hydraulic down feed pressure and CPT feed rate controls provide precise pressure and penetration adjustments required to meet ASTM standards. A separate CPT system hydraulic pressure gauge is provided as well. Anchor points are installed below the drill feed frame so that maximum available pressure can be applied to the CPT tools. A 12-volt power source can be provided at the drill control panel to accommodate electronic devices associated with CPT procedures. Mounting for depth transducers or other related equipment can also be provided.

Additional optional equipment

- Spindle adaptor

- Fluted kelly and chuck systems

- Water swivel

- Mast (from base of frame to sheaves)

- 20 foot (6.1 m)

- 22 foot (6.7 m)

- Hydraulic cathead

- Hydraulic hoist

- 1,800 pound (816 kg)

- 3,200 pound (1,452 kg)

- 7,000 pound (3,175 kg)

- 8,500 pound (3,856 kg)

- Hydraulic wireline hoist

- 1,800 pound (816 kg), max line speed 200 ft./min (61 m/min)

- 900 pound (408 kg), max line speed 400 ft./min (122 m/min)

- Water pumps

- Moyno 3L6 36 gpm/225 psi (136 lpm/1,551 kPa)

- Bean L09 (420) 25 gpm/500 psi ( 95 lpm/3,448 kPa)

- Bean L1122 (435) 40 gpm/500 psi (152 lpm/3,448 kPa)

- Other pumps available

† Patented by Central Mine Equipment Company

55 Features | 55 Specifications | 55 Optional Equipment

Performance ratings are based on engineering specifications, calculations and accepted industry standards.

Capacities may vary according to drilling conditions. CME reserves the right to amend these specifications at any time, without notice.