CME-55 Truck Mounted Drill Optional Equipment

Rubber Tire ATV Mounted Drills | Truck Mounted Drills | Track Carrier Mounted Drills | Trailer Mounted Drills | Skid Mounted Drills

55 Features | 55 Specifications | 55 Optional Equipment

Automatic SPT hammer†

Our 140 pound (63.5 kg) automatic hammer gives you extremely consistent and accurate Standard Penetration Test results, meeting all ASTM-D-1586 requirements. That’s because there are no ropes or cables to impede the free fall of the weight. The hammer swings from stored position to on-hole position. Since raising and lowering is done hydraulically, set up is quick and almost effortless. For maximum safety, all moving parts are enclosed, including the impact area between the weight and the anvil. Other hammer sizes are available including 170 pound (77.1 kg), 300 pound (136.1 kg), and 340 pound (154.2 kg).

Hydraulic rod holder and breakout wrench†

Slide bases make the job easier and quicker

Slide base options are available for both in-out and sideways movement of the drill on the platform. An 18 inch (46cm) in-out movement allows you to quickly move the drill off the bore hole and align the sheaves for lifting tools with the cathead or any of the hoists. A 16 inch (41cm) sideways movement gives you even more versatility. Aligning the augers or rods when making connections is easy, or if the bit drifts off at an angle when starting a hole, you can quickly straighten it to a vertical position. Since the upright and optional mast are mounted directly to the drill frame, they move with the drill when the slide base is used. That means you can drill in any position within a 288 square inch (1,858 sq cm) area without moving the carrier. If you have ever tried lining up your rig over an existing bore hole, you probably recognize the benefit of the slide bases.

Quick mast disconnect†

This feature allows you to quickly disconnect the mast when working inside buildings, underneath bridges or in other low overhead drilling locations. Since the mast is completely separated from the upright, it doesn’t interfere with other drill functions such as the in-out slide base. With the mast in the horizontal position, you simply clamp it to its storage rack and extend the drill’s in-out slide base. This pulls the sockets on the upright drill frame away from the large tapered pins on the mast.

Patented angle drilling system†

This unique system is especially effective for drilling underneath ponds, storage tanks, or other structures. When used with our patented continuous sample tube system, you can even take soil samples while drilling angle holes. The angle drilling system will also allow you to drill vertically with the carrier positioned on an uphill slope. This eliminates the time-consuming job of leveling the rig. And, since the kelly drive is always coupled to the right angle drive box, you can raise and lower the mast with the drivetrain already connected and ready to go.

Fluted kelly and chuck assembly†

If your drilling operations include a substantial amount of rotary or core drilling, the CME fluted kelly and chuck assembly can save you a lot of time. The 5 foot (1.5 m) stroke of the kelly, combined with 6 foot (1.8 m) stroke of the feed system, gives you a total stroke 11 feet (3.4 m). You can use 10 foot (3 m) drill rods, which means fewer rod connections and less rod handling. The kelly has two vertical slots (flutes) and two sets of horizontal slots which are engaged by the chuck to provide rotary torque and thrust. The CME fluted kelly can even be rotated without engaging the thrust keys. This gives you the option of using the weight of the drill string to provide down pressure on the bit. The 2 5/8 inch (6.7 cm) fluted kelly and chuck assembly is available in either manual or hydraulic actuated configurations. Or if you are drilling larger diameter holes, a 3 1/2 inch (8.9 cm) O.D. fluted kelly and hydraulic chuck assembly is available.

Cone Penetrometer Testing (CPT)

CPT controls allow you to easily switch from typical geotechnical drilling and sampling procedures to pushing a cone. A dedicated hydraulic circuit including detented CPT control lever, hydraulic down feed pressure and CPT feed rate controls provide precise pressure and penetration adjustments required to meet ASTM standards. A separate CPT system hydraulic pressure gauge is provided as well. Anchor points are installed below the drill feed frame so that maximum available pressure can be applied to the CPT tools. A 12-volt power source can be provided at the drill control panel to accommodate electronic devices associated with CPT procedures. Mounting for depth transducers or other related equipment can also be provided.

Additional optional equipment

- Drill platform

- Auger racks

- Rod racks

- Tool boxes

- Water tanks

- Work tables

- Leveling jacks

- Auger and rod guides for angle drilling

- Spindle adaptor

- Water swivel

- Air compressor (engine mounted) and impact wrench

- Work lights

- Mast (from slide base to sheaves)

- 20 foot (6.1 m)

- 22 foot (6.7 m)

- 26 foot (7.9 m)

- Cathead

- Hydraulic hoist

- 1,800 pound (816 kg)

- 3,200 pound (1,452 kg)

- 7,000 pound (3,175 kg)

- 8,500 pound (3,856 kg)

- Hydraulic wireline hoist

- 1,800 pound (816 kg), max line speed 200 ft./min (61 m/min)

- 900 pound (408 kg), max line speed 400 ft./min (122 m/min)

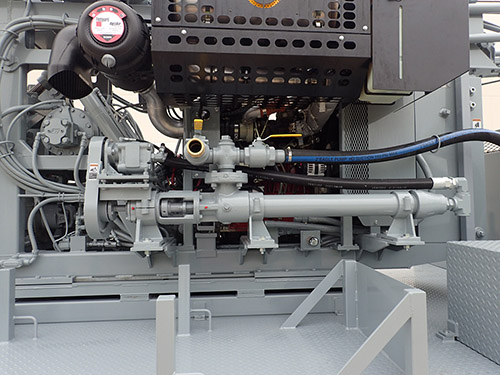

- Water pumps

- Moyno 3L6 36 gpm/225 psi (136 lpm/1,551 kPa)

- Moyno 3L8 84 gpm/225 psi (318 lpm/1,551 kPa)

- Bean L09 (420) 25 gpm/500 psi ( 95 lpm/3,448 kPa)

- Bean L1122 (435) 40 gpm/500 psi (152 lpm/3,448 kPa)

- Other pumps available

† Patented by Central Mine Equipment Company

55 Features | 55 Specifications | 55 Optional Equipment

Performance ratings are based on engineering specifications, calculations and accepted industry standards.

Capacities may vary according to drilling conditions. CME reserves the right to amend these specifications at any time, without notice.