Hollow Stem Auger (HSA) Center Hexagon Drive System

Hollow Stem Augers | Hollow Stem Auger Assembly | Hollow Stem Auger Center Drive System | Hollow Stem Auger Accessories | S-Series Cutter Heads | Hollow Stem Auger Sizes | Continuous Flight Augers

For large diameter holes and tough drilling conditions.

If your drilling operations include large diameter auger jobs… or, if you’re frequently drilling in especially difficult formations, CME’s center hexagon drive system can save you time and money. Large diameter auger drilling or tough drilling conditions can over-torque threaded connections on center drill rods. Over-torqued connections can be extremely difficult and time consuming to break-out. Excessive torque can also shorten the life of threaded

drill rod connections. CME’s center hexagon drive system has no threaded connections. You simply slide the box and pin hex ends together and install the drive pin. When coming out of the hole, a slide connector allows you to separate the hollow auger connection and access the hexagon rod connection inside. You simply knock out the drive pin and slide the rods apart.

A big advantage in wet sands

Drilling and sampling in wet sands can be a real challenge. During drilling operations, sand tends to pass between the pilot assembly and the inside diameter of the hollow auger. The sand can bridge the annulus of the auger above the pilot assembly and form a plug. This plug will not only make it difficult to pull the center rod string, it will also cause a vacuum to form below the center head. As you raise the center rod string, even more sand will be drawn up inside the center of the augers. CME’s center hexagon drive system with reverse flighting lead stem provides an open area between the center head and the inside wall of the hollow auger. This helps to prevent sand from bridging in the annulus of the auger. The reverse flighting on the lead center stem also works against sand trying to move up inside the auger column.

Special alloy steel for maximum durability

CME’s hexagon rods are made from special alloy steel and are heat treated for maximum strength and durability. Center hexagon rod systems are available for use with all CME hollow stem augers 3-1/4" (8.3 cm) ID and larger.

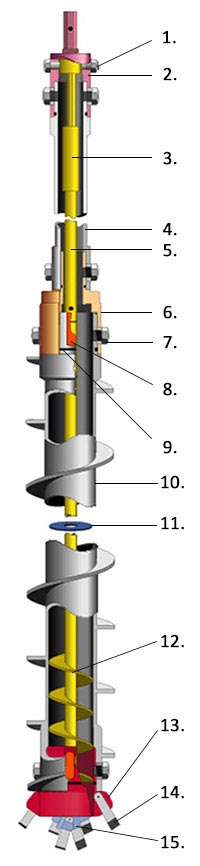

2. Drive cap - The CME hollow auger drive cap has a shank to fit the drill spindle adaptor assembly and a keyed auger box coupling that fits over a hollow auger pin coupling.

3. Slide connector - Connects drive cap to internal hex rod assembly. When an auger coupling is disconnected, the slide connector allows you to raise the auger above the joint and access the internal hex rod connection.

4. Auger stem - Extension which connects the drive cap to the auger sub.

5. Hex rod drill stem - Drill stem with hexagon pin and box connections which are secured with a drive pin. Since it has no threads, hexagon connection will not unscrew during reverse rotation.

6. Auger sub - Adapts auger stem to larger diameter hollow auger.

7. Auger connector bolt - Secures hollow auger connections.

8. Key-way - Allows augers to be rotated in forward or reverse under full rotary power while applying down pressure or retract forces to the auger column.

9. Patented O-ring seal - O-ring seal installed in groove on auger pin helps prevent contaminates from leaking into the auger column and drilling fluids from leaking out.

10. Hollow stem auger section - Auger flighting diameters and pitch are designed for maximum conveyance of soil cuttings with a minimum of drilling torque. Entire length of flighting is hardsurfaced for long-term abrasive wear resistance.

11. Guide ring - Keeps drill stem centered inside hollow stem auger column.

12. Lead center stem - Drill stem with unique reverse flighting helps prevent cuttings from plugging the bottom of the auger column. If cuttings do enter the auger column, reverse flighting allows you to rotate and easily pull out.

13. Auger head - Multi-use hollow auger head with replaceable forged steel, tungsten caride tipped teeth.

14. Replaceable carbide insert tooth - Easily changeable forged steel, tungsten carbide tipped teeth feature the best combination of hardness and durability for optimum cutting efficiency and long life.

15. Center head - Center heads used with 3-1/4" (8.3 cm) through 3-3/4" (9.5 cm) ID hollow augers are completely replaceable. Center heads used with 4-1/4" (10.8 cm) ID hollow augers can be either completely replaceable or have replaceable teeth. Center heads used with larger hollow augers have replaceable teeth.

See Product Catalog for Part Numbers, Accessories, and Replacement Items