Rubber Tire ATV Mounted Drills | Truck Mounted Drills | Track Carrier Mounted Drills | Trailer Mounted Drills | Skid Mounted Drills

55LC Features | 55LC Specifications | 55LC Optional Equipment

The quick disconnect mast can be secured in its storage rack and removed from the drill by simply sliding the drill back with the hydraulic in/out slide base control. “Quick-cabling” sheaves allow you to easily move the hoist lines from the mast sheaves to the low clearance sheaves provided above the drill frame.

The CME-55LC is powered by a Cummins QSF 3.8 turbocharged diesel engine meeting tier-4 final emissions standards. Cold weather starting aid and engine protection shutdown systems are standard equipment.

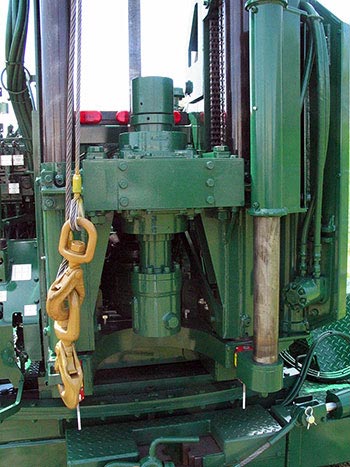

Rugged mechanical standard rotary drive provides 7,780 foot pounds (10,548 Nm) of torque and rotary speeds of up to 800 rpm. Other rotation and torque combinations are available, including a high-torque rotary drive that gives you up to 9,425 foot pounds (12,778 Nm) of torque and rotary speeds of up to 665 rpm. The five speed transmission is connected to the drill engine through a heavy-duty 13 inch clutch. With five forward gears and one reverse, there is a rotation speed and torque combination for just about any situation. The mechanical drive system also gives you a better feel for drilling conditions down the hole. It allows you to sense the need for changes in feed pressure and rotational torque.

Our emergency spindle brake can stop rotation in less than a revolution. The system is activated by two conveniently located push button switches as well as strategically located multi-directional wobble switches.

The CME-55T trailer is designed specifically for CME-55 drills which means best possible weight distribution and use of available space. Four tool boxes provide plenty of storage. Tool boxes are mounted forward to help distribute the weight evenly on the trailer. Drill rod and auger rack are mounted over the fenders on both sides of the CME-55T trailer.

The CME-55T trailer is equipped with three hydraulic leveling jacks. Two jacks are mounted at the rear and a third is at the front. The 36-stroke jack cylinders make it easy to level the rig regardless of the site conditions.

† Patented by Central Mine Equipment Company

55LC Features | 55LC Specifications | 55LC Optional Equipment

Performance ratings are based on engineering specifications, calculations and accepted industry standards.

Capacities may vary according to drilling conditions. CME reserves the right to amend these specifications at any time, without notice.

Call 1-800-325-8827 for more information! |

Home | Request-a-Quote | About Us | Contact Us | Product Support Team | Drill Rigs | Hollow Stem Augers | Continuous Flight Augers | Continuous Sample Tube Systems | Support Equipment | Tooling & Supplies Rig Repair & Upgrades | Product Line | CME Product Catalog | Brochures | CME Videos | Sign Up for Monthly Product Updates | Product Update Archives | Upcoming Events | Privacy Statement | Sitemap Rubber Tire ATV Mounted Drills | Truck Mounted Drills | Track Mounted Drills | Trailer Mounted Drills | Skid Mounted Drills Copyright© 2025. Central Mine Equipment Company. A Missouri Corporation. All rights reserved. 4215 Rider Trail North · Earth City, MO 63045 · (800) 325-8827 · (314) 291-7700 · info@cmeco.com · www.cmeco.com 8:00 a.m. - 4:30 p.m. Central Time (CT) Proudly made in the U.S.A. since 1928.

|